What is the UGRA-Fogra Media Wedge 3.0 used for?

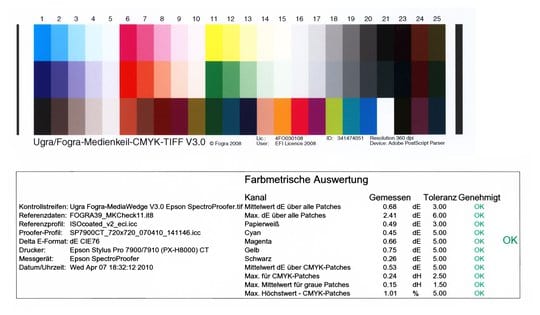

Every print shop in Germany adheres to a predefined standard, the process standard offset printing. This standard defines target and tolerance values for printed products. In order to prove that your proof delivered to the print shop meets these standards or is within the tolerances, the media wedge is measured and the values analysed in case of doubt – i.e. in case of a streak. If these measured values are correct, the print shop is obliged to adhere to and achieve these values. Practice generally shows the following: If you …