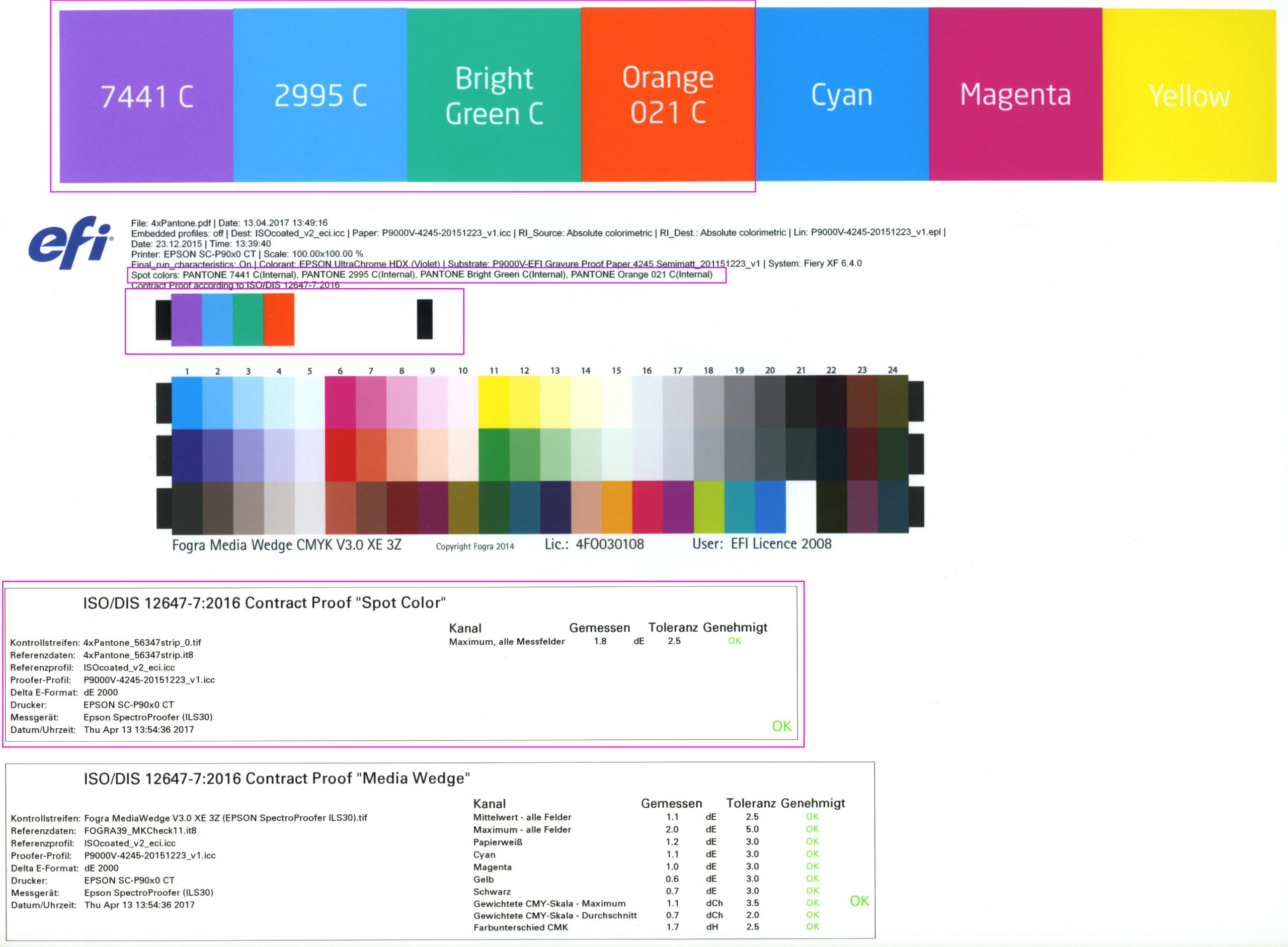

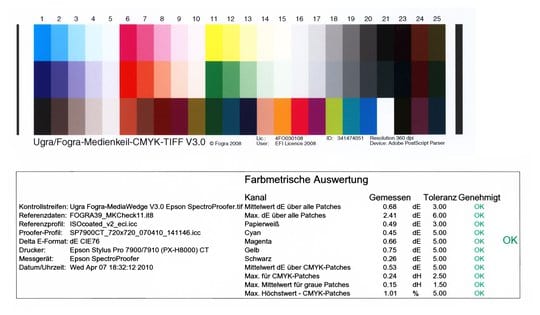

The ISO 12647-7 proofing standard was revised in November 2016 and the test criteria for FograCert contract proof creation were adapted. We have now incorporated these changed criteria into our proofing system and are now working to the stricter tolerances of the latest ISO 12647-7:2016.

Why hardly anything changes for our Proof customers

The good news is: you won’t notice that our proofs are now precisely produced according to the latest standards. Why? Quite simply: Because our demands on our proofing system, our FIERY proofing software, our EFI proofing papers and the X-Rite measuring decvices are already so high that all components of our proofing system – and of course our proofs themselves – have been meeting the new criteria of the revised November 2016 standard for years.