A proof is suitable for two types of color control: firstly, during the creation or retouching phase, e.g. to reconcile a color retouched image with the original, and secondly to check the final data directly before printing.

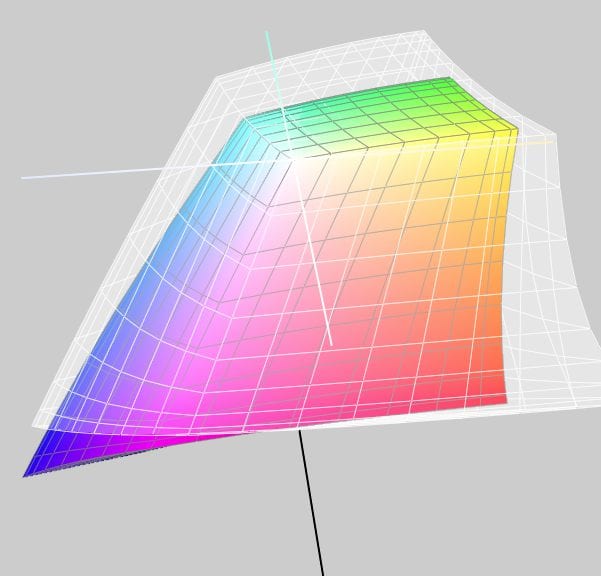

For control proofs during the data creation of a project, the data format usually does not matter. Whether PDF, JPEG, TIFF; EPS, PS or even PSD… Many proofing companies accept a variety of data formats. For a correct evaluation of the result, however, it is important to proof in the color space in which the print product is also created later. Data for a letterhead should therefore be proofed in ISOUncoated or PSOUncoated, while products printed on image printing paper should be proofed in ISOCoatedV2. For yellowish paper, newsprint or gravure printing, there are many other profiles for which a proof can be produced. You can find a good overview of the current proof profiles here. It is also important that the proof format and the final print format do not differ too much. Only in this way is a correct check possible.

Read more