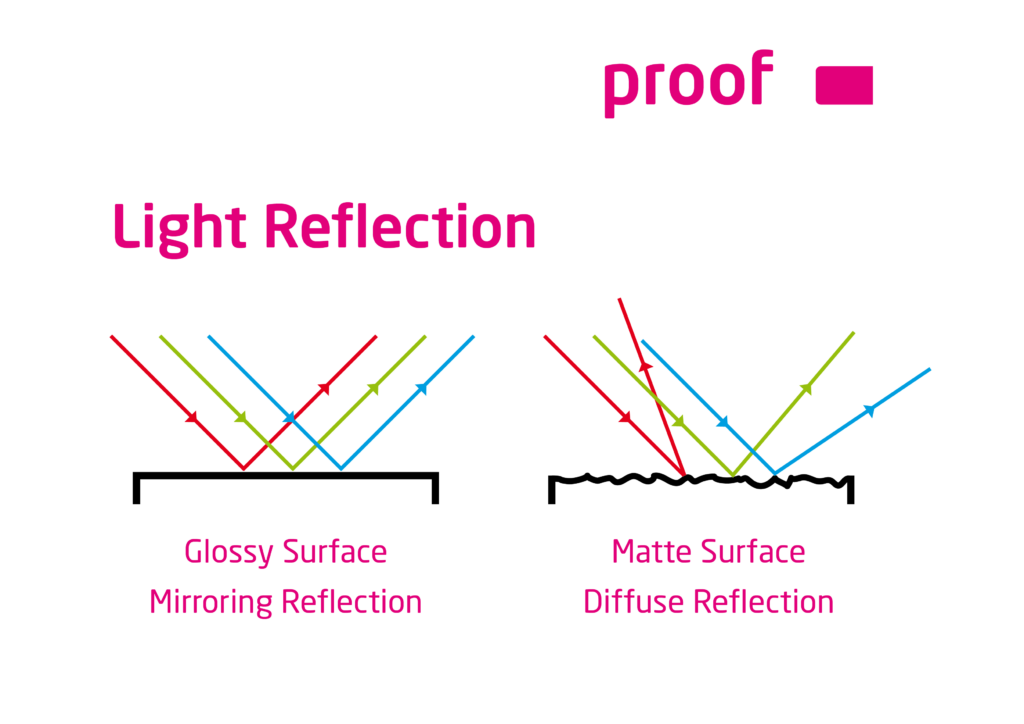

Different surfaces can influence both the colour and the appearance of objects. A colourful and glossy object will usually appear more saturated to the eye, while a similar object with a matte, diffuse surface will appear duller.

If you form a glossy, a semi-matte and a matte surface from the same black plastic, the glossy surface will often appear blackest, while the very matte surface will appear much lighter. The same effect can be reproduced with film lamination of prints: a glossy laminated dark blue or black appears more saturated and darker, a matt laminated black becomes lighter and greyer to the human eye due to diffuse light refraction.

Humans perceive the colour of objects through the light reflected from them, and different surfaces reflect light differently. In general, therefore, there are two ways in which light is reflected from an object: The specular and the diffuse reflection.

Specular reflection

Specular reflection occurs when light is reflected from the light source at an equal but opposite angle. Simply put, you can think of it as a ball bouncing off a smooth floor and bouncing back at the same angle. This reflection occurs mainly on objects with shiny, smooth surfaces.

Diffuse reflection

If, on the other hand, the reflected light is scattered in numerous different directions, we speak of diffuse reflection. This reflection occurs on objects with matt and irregular surfaces. A ball would bounce off such a surface – for example, an irregular floor consisting of numerous pyramids of different sizes – sometimes at one angle and sometimes at a completely different angle.

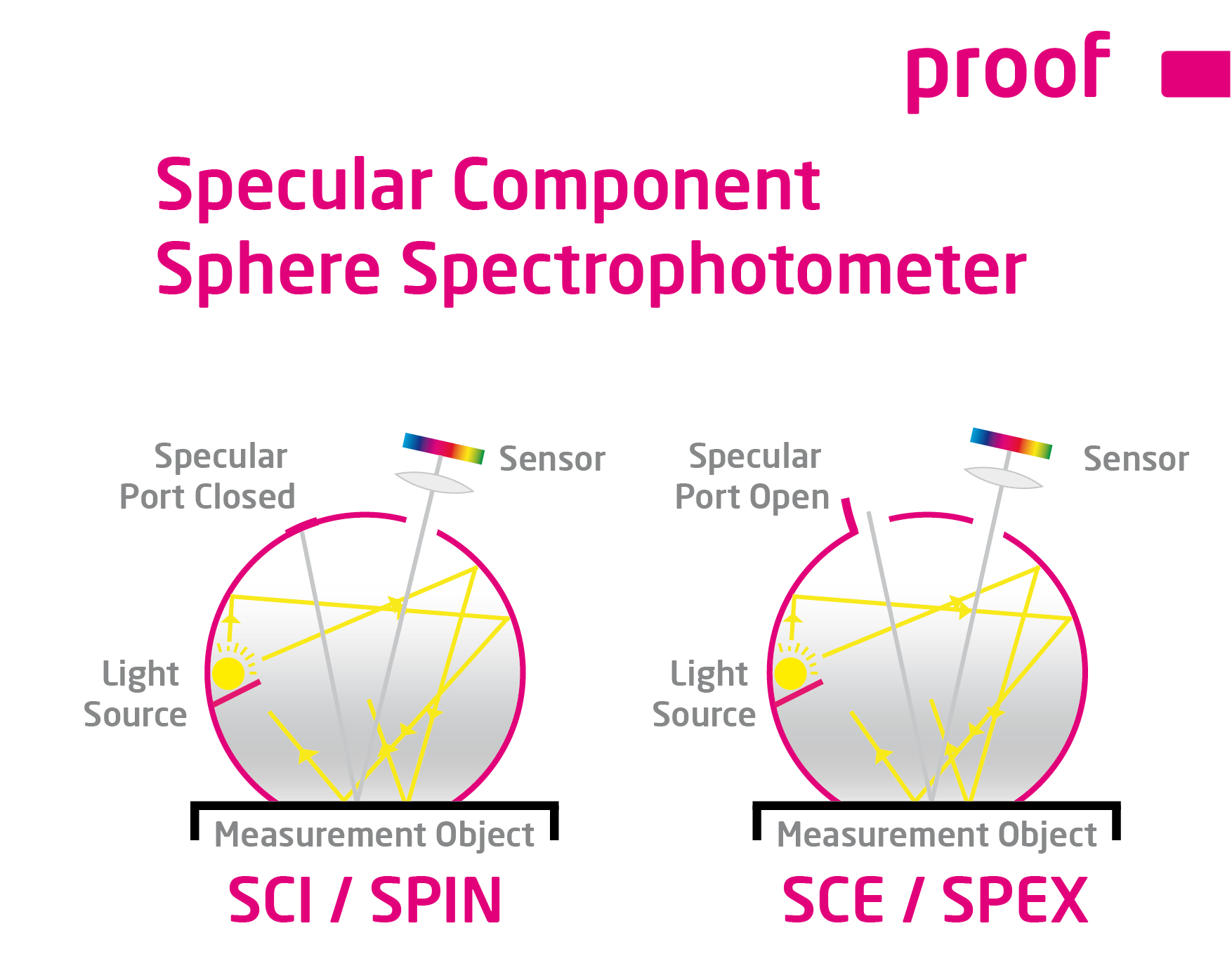

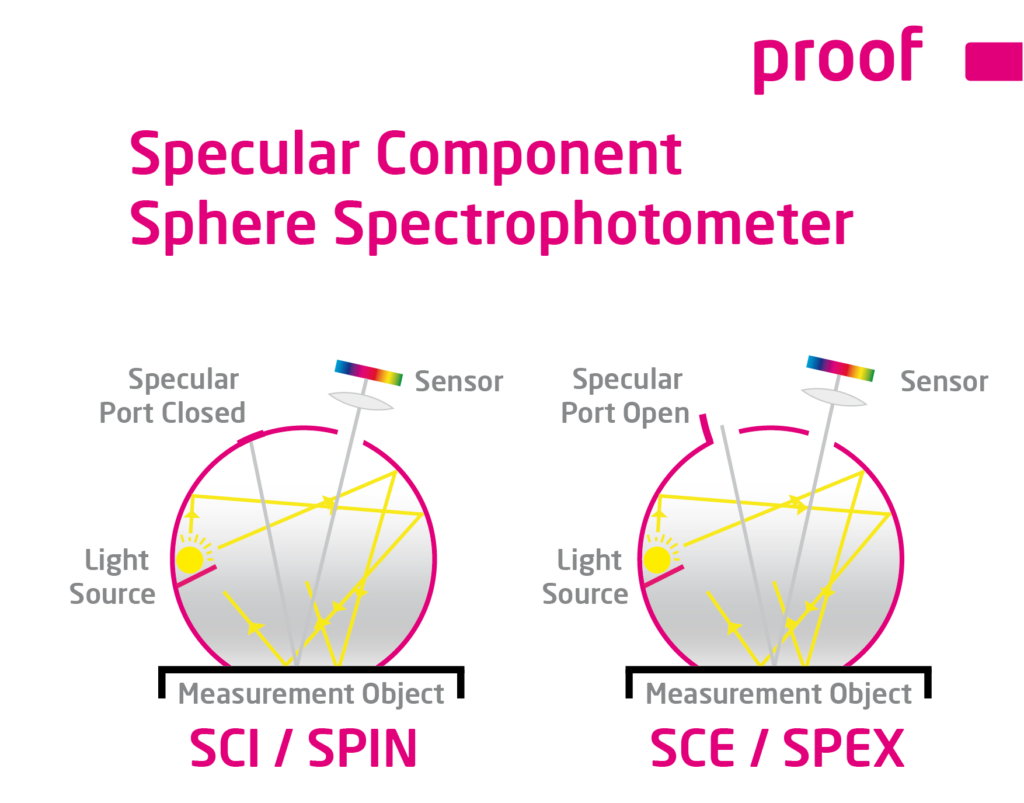

Spectrophotometers with an integrating sphere

Today, when colour and gloss are to be evaluated in global supply chains and on different surfaces, this is often done with sphere head spectrophotometers such as the KonicaMinolta CM-26d, with which we at Proof GmbH have also measured the semi-matt and matt free-colour CIELAB HLC Colour Alas XL. With the d:8° geometry and the integrated 60° gloss sensor, which can handle both the SCI – “Specular Component Included” and SCE – “Specular Component Excluded” measuring modes, this measuring device can measure colour and gloss within less than a second without having to use an additional measuring device for gloss and always having to be set up and aligned again.

With integrating sphere measuring instruments, the surfaces to be measured are usually illuminated at all angles and measured at an angle of 8 degrees from the vertical axis. This measurement condition is referred to as d/8 or d:8. Most of the integrating sphere measuring devices such as the CM-26d can measure with or without a gloss component as previously described.

In contrast, the 45/0 models used in the printing industry such as the X-Rite i1 Pro2 always measure without the specular reflection. The reflection of the sample surface is therefore perceived differently by the optical geometries d:8 with gloss component – SCI – , d:8 without gloss component – SCE – and 45/0 respectively.

SCI measurement mode

To measure the true colour of an object without the influence of surface texture, the Specular Component Included (SCI) measurement mode is used. SCI mode includes both specular and diffuse reflected light and is ideal for quality control and colour quality monitoring.

- Illuminates the sample evenly from all sides.

- Takes into account the total surface reflection.

- Has good repeatability and is insensitive to surface variations or artefacts.

- Does not perceive gloss differences of the sample and therefore does not simulate visual assessment.

SCE measurement mode

The Specular Component Excluded (SCE) measurement mode, on the other hand, which excludes specularly reflected light, is used to evaluate the colour of an object to match the visual perception of the human eye. In SCE mode, a glossy surface is typically measured darker than a matte surface of the same colour; similar to how the human eye sees it. This mode is typically used in quality control testing to ensure that colour matches colour standards through visual inspection.

- Illuminates the sample evenly from all sides, but not in the reflection angle of the measurement.

- Excludes specular surface reflection, although usually not completely

- Includes diffuse surface reflection.

- Is somewhat sensitive to surface variability and unevenness.

- Measures the colour of a surface similar to how the human eye sees it.

No related posts found...