For 20 years now, PDF/X standards have been available for the printing industry and have enjoyed great popularity. Now, with the introduction of PDF 2.0 in 2017, another milestone in PDF standards has been introduced, having been developed by numerous PDF experts over many years. And just recently, the ISO published a new revision of PDF 2.0. Soon, the new printing standard PDF/X-6 will also take shape, which contains several innovations in detail compared to PDF/X-3 published in 2002 and PDF/X-4 adopted in 2008. The old PDF standards will retain their validity, but the new ones will certainly find their way successively into the software and processes of the printing industry.

For 20 years now, PDF/X standards have been available for the printing industry and have enjoyed great popularity. Now, with the introduction of PDF 2.0 in 2017, another milestone in PDF standards has been introduced, having been developed by numerous PDF experts over many years. And just recently, the ISO published a new revision of PDF 2.0. Soon, the new printing standard PDF/X-6 will also take shape, which contains several innovations in detail compared to PDF/X-3 published in 2002 and PDF/X-4 adopted in 2008. The old PDF standards will retain their validity, but the new ones will certainly find their way successively into the software and processes of the printing industry.

New in PDF 2.0:

- PDF/A-4 according to ISO 19905-4:2020 – PDFs for archiving

- PDF/X-6 according to ISO 15930-9:2020 – PDFs for professional printing

- The most important innovation is the page-based output intent: A brochure whose cover is printed on coated paper and the inner part on uncoated paper can now be exported as one PDF file with two output conditions: PSOCoatedV3 and PSOUncoatedV3, mixed according to pages. Previously, a file could only contain one output profile. Also new is the depth compensation and the embedding of spectral data for spot colours according to CxF-4. This makes it possible to transfer spot colours with a spectral definition and not just write a LAB or CMYK value into the PDF. Also new is the support of multicolour profiles, i.e. ICC profiles with more than four colour channels. The new PDF/X-6 standard is very similar to PDF/X-4 in many aspects.

- PDF/VT-3 according to ISO 16612-3:2020 – PDF exchange format for transactional printing

- The term transactional printing may not be familiar to many media designers. It covers the printing and processing of data for the creation and printing of invoices or account statements, for example. Transactional printing refers to all processes, i.e. from the export of data from an SAP system etc. to the printing, processing and dispatch by post or email to the return of the dispatch into SAP. The new VT-3 PDF standard specifies the parameters for this variable, transactional printing.

- PDF/R-1 according to ISO 23504-1:2020 for scanning in PDF data

- A brand new standard is the R-1 PDF standard, the “raster” standard. Developed by the Twain people, it is only relevant for the creation of raster image documents, i.e. scans of pages or images.

The most important innovations for us in the printing sector with the introduction of the PDF 2.0 standard are, of course, the PDF/X innovations with the leap from PDF/X-4 to PDF/X-6, which is being developed on the basis of PDF 2.0.

- Page-related output conditions: The best examples of applications in these areas are certainly brochures with covers: If, for example, the cover was previously printed in 4/4 colour on glossy picture print and the inner section on uncoated paper, then this could only be realised via two PDFs, one for the cover, one for the inner section. Now a brochure PDF can carry both output conditions, even a colourful cover and a black and white inner section can be combined into one PDF.

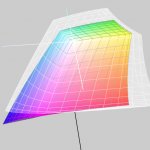

But in application we would certainly like to use this for typesetting work at any time. For us in proofing, this probably has little practical effect, because coated and uncoated paper would also be printed on different proofing papers, so we would have to split the one file into two proofing jobs. Of course, we could also go the comfortable way and proof the uncoated paper on a proof paper for coated paper, but this would not be very comfortable for the viewer in terms of the effect. Sampling a natural paper interior from a natural paper proof onto the production paper is much more coherent and visually better. In laser print-based environments, however, individual paper trays and processing methods of a printer could be assigned to profiles, for example, so that these features could be better used here in daily work. Up to now, this could be done via a job ticket that was created and processed with the PDF file, but now it could be done directly in a document. - Spectral data according to CxF-4: Spot colours can now be defined spectrally. The new CxF-4 format, which has also become an ISO standard, is used for this. This is certainly important in two cases: On the one hand, spectral data can contribute to a more precise colour definition of spot colours than pure LAB, RGB or CMYK values are capable of. Especially on modern seven- and multi-colour printing systems with their enormous colour gamut, almost the entire PANTONE colour palette can be reproduced. Especially here, the use of spectral spot colour definitions would certainly prove its worth.

For us, this is not really an issue in proofing at the moment, as we will probably see little spectral data in customer data. However, in our special applications such as the HLC Colour Atlas or the production of calibration targets for customers, we could well imagine the more frequent use of spectral data. In the new generation of ICC profiles, multicolour ICC profiles can also be used, and the colour sequence in the printing units and the overprinting behaviour can now be better defined. Here, too, we are curious to see how the latest developments will find their way into our work.