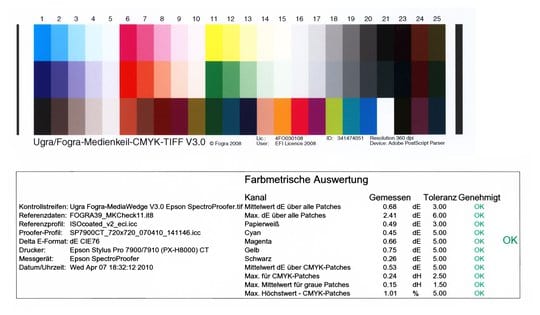

A proof is prepared according to the currently valid ISO standard 12647-7 and is legally binding with a UGRA-Fogra media wedge and measurement report.

How does this check work?

If you need a proof with UGRA/Fogra Media Wedge CMYK V3.0, there are two ways to add the test report to your data.

- With proofing devices in which a measuring device is integrated, the media wedge with 3×24 standardised colour fields is printed directly under the proof data. This media wedge is driven directly in the proofing device to a kind of “hair dryer” in the measuring device and dried there. After a few minutes of drying, the media wedge continues and is measured directly in the proofer. This takes a few minutes. The measured values determined in this way are returned to the proof server and evaluated there. If the colour values are correct and within the tolerances of the strict ISO standard, a test report of the measurement is then printed directly under the media wedge, which guarantees you colour accuracy in accordance with the process standard offset printing.

- For proofing devices without integrated measuring device, only the standardized media wedge is printed under the proof data. A check takes place subsequently and outside the proof printer. The media wedge is then measured with an external measuring device and the target and tolerance values are output to a label printer. This label is then stuck directly under the media wedge.

What is the advantage of automated creation and checking of the media wedge directly in the proofing device?

- Measurement is automated directly after proof printing, measurement errors due to manual operating errors are excluded. Since the test report is not subsequently attached, as is often still the case, manipulation is impossible.

Further information on the test report, the media wedge and on the work and responsibility of UGRA/Fogra can be found at www.ugra.ch and www.fogra.org.

In this short image video we – the Proof GmbH – introduce us and our work. Find out who we are and what drives us. What do you think of our short film?

Even almost 9 years after the introduction of the successor colour space PSOCoatedV3, ISOCoatedV2 / FOGRA39 is still the most widespread colour space in Europe. We at Proof GmbH count around 200 jobs from time to time for the German Printing and Media Industries Federation, among others. In the last count, proofs in ISOCoatedV2 accounted for around 68% of all proof jobs at our company. This is a clear sign of the continued widespread use of the colour space. ISOCoatedV2: From the classic colour space to the beacon of the … read more

Proof GmbH is a member of Fogra – Forschungsinstitut für Medientechnologien e.V.. Why? In recent years, we have been able to draw on the support of Fogra with numerous projects, or work together with Fogra, for example for Fogra58 beta – Textile-RGB (where Matthias Betz was also able to report on our experiences as a speaker at the Fogra Colour Management Symposium 2020 in Munich as part of the presentation “Proofing of Fogra58beta”) or have contributed test prints and proofs to the research project “11.004L – Improving the printability … read more

Offset and Newsprint ISO Coated v2 (ECI) / ISO Coated v2 300% (ECI) Profile: ISOcoated_v2_eci.icc Standard for glossy and matte coated paper Paper: Types 1 and 2, gloss and matte coated Tone value increase curves A (CMY) and B (K) as defined in ISO 12647-2:2004 Characterisation Data: FOGRA39L ISOUncoated Profile: ISOUncoated.icc Standard for uncoated white natural paper Paper: paper grade 4, uncoated white offset, dot gain curves C (CMY) and D (K) from ISO 12647-2: 2004 Characterisation Data: FOGRA29L PSOCoatedV3 / Fogra 51 Profile: PSOcoated_v3.icc The successor of ISOCoatedV2 for glossy … read more

The most important colour management event takes place every two years in Munich: the Fogra Colour Management Symposium. Once again this year, all professionals are invited to make the pilgrimage to Munich: two days of lectures, discussions and a Bavarian evening await participants. Matthias Betz, owner of proof.de, will also be there again: for many years, he has been taking advantage of the opportunity to exchange ideas with colleagues and friends, learn about new technologies, hardware and software, and talk to colleagues from Fogra, freieFarbe, GMG and many more. In … read more

Once again we passed the Fogra certifications and were even the first company to be certified with the Fogra “Spot cert” for Fogra59 eciCMYK-V2.

In the current issue of Fogra News “Fogra Aktuell” Proof GmbH is involved in two places. Firstly, a summary of the Fogra report on our first FOGRA55 certification for seven-colour printing with extended colour space in CMYKOGV appeared. You can also find more information on our FOGRA55 certification on the Fogra website: https://fogra.org/en/press-releases/fogracert-erste-cpc-zertifizierung-fuer-fogra55-cmykogv-330 and on proofing.de: And secondly, there was a report on the completion of the research project for textile digital printing, FOGRA58, in which we were allowed to investigate and test the proof capability of the new textile … read more

In 2021 proof.de was again Fogra certified including Fogra “Spot cert” certification, i.e. for the display of spot colours such as PANTONE C and U.

The 7th Fogra Color Management Symposium was held in Munich from February 12 to 13, 2020, to which I was invited as a speaker for the area of proofing in Session 6. I reported on our tests in proofing for the Fogra58-Beta-Textile-RGB Standard for textile digital printing. The Fogra Color Management Symposium is one of the events in the field of colour management and brings together scientists and users from all over the world for a two-day exchange of ideas in Munich. A total of 21 speakers and 7 moderators … read more

Digimarc is a digital watermark that can be used to embed information in images, videos or other media. Digimarc watermarks are invisible to the human eye, but remain recognisable to special software or devices. Digimarc is becoming increasingly popular in the packaging sector in particular, as this technology allows the digits of the EAN barcode and more to be applied invisibly to all areas of the packaging. Digimarc and EAN barcode at the supermarket checkout When scanning at the checkout, the checkout staff do not have to search for the … read more