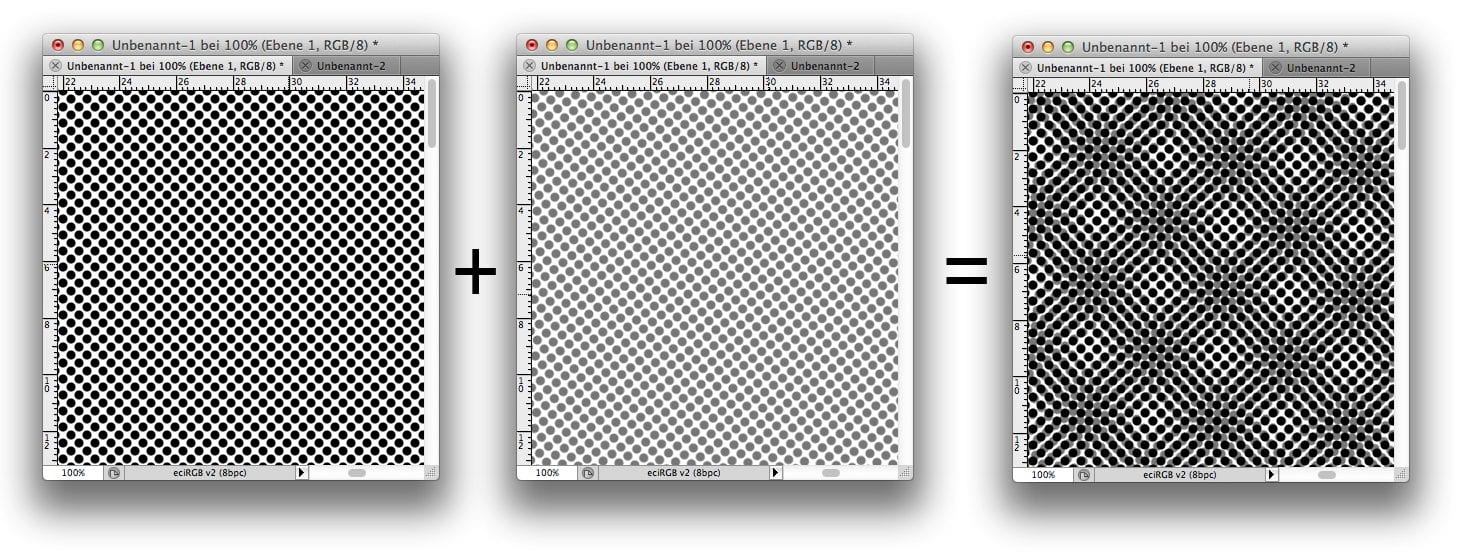

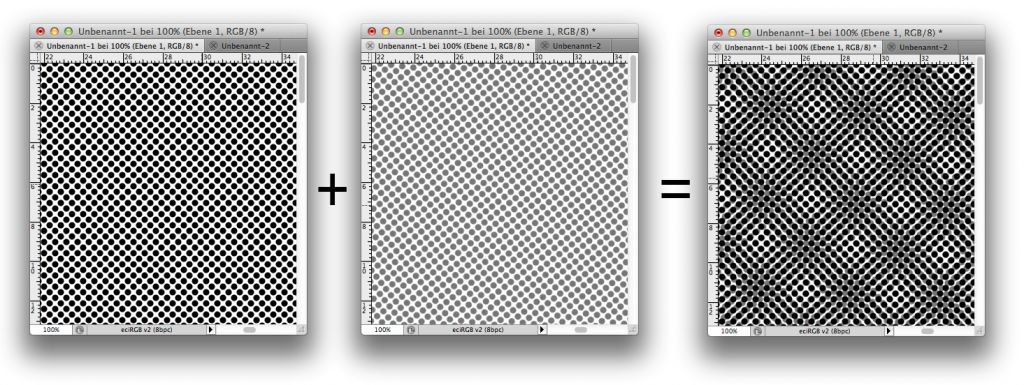

The Moiré effect, or in other words a halftone screen overlay, is a common phenomenon when viewing prints. It occurs when two even patterns overlap unevenly.

When does Moiré appear?

Moire is always created when screens overlap. Typical examples:

- You have scanned in a newspaper ad and print it in another newspaper.

- You print the portrait of a managing director wearing a jacket with a fine houndstooth pattern, a checkered shirt and a finely patterned tie. Regardless of the printing process, complete moiré chaos is guaranteed to break out here.

- A brick building is reproduced in offset printing.

- The photograph of a ventilation grille is viewed on a monitor

No Moiré occurs when:

- The motif is printed large enough, e.g. on a trade fair wall, so that no grid overlapping occurs. The print screen is sufficiently fine to reproduce the image screen completely.

- The motif is printed small enough so that no screen overlay occurs. If the check shirt is printed so small that no more check can be reproduced, Moiré will no longer appear.

- Printed in a frequency modulated screen. If the screen is distributed seemingly chaotically over the page, the chance of an overlay is significantly minimized.

You will find numerous examples of Moiré images in the Google image search. Particularly exciting: checkered shirts in different magnification levels. Have a look and search!

For the most part, moiré cannot be checked in a proof.

All common proofing systems concentrate on the reproduction of colours during proofing, but not on the reproduction of the typical offset screen and offset rosette. Why is that?

Printers work with different screen widths and screen angles. From 54 to 80 screens in sheetfed offset to 32 screens in newspaper printing, there are many screens on the market. Sometimes the screen dot is round, sometimes square, sometimes diamond-shaped. In addition, the screen angle of CMYK and spot colours also varies from printer to printer. And some printing companies also print a frequency-modulated screen that is not subject to screen angles but is produced practically randomly by the RIP. As a result, proofing companies mainly concentrate on the reproduction of colours, but not of screens and offset rosettes.

The most common proofs are produced as detailed as possible in inkjet printing without raster reproduction. In addition, proofing software manufacturers often use other calculation algorithms to make the proofs look more realistic. While in practice EFI proofs often look much fuzzier than modern offset prints printed via CTP, GMG uses artificial noise to make its proofs “look bad” and thus possibly better match the printed result. It remains to be seen whether this is useful and effective, but it also leads even further away from a recognizable Moiré.

Reliably detecting Moiré is expensive.

The only way to reliably predict possible Moiré is a press proof according to the precisely identical screen and screen angle specifications of the printer who prints the run, i.e. optimally a press proof at the same printer with the same prepress and on the same press on which the final print will later run. This is expensive, but it accurately shows the final print.

A test print at Flyeralarm is no solution.

Although Flyeralarm mainly prints the supplied data in a very high quality and accurate way, screen spacing and screen angle are certainly not identical to those of the local printing house. The Moiré at Flyeralarm is therefore certainly not comparable with that of the local printing house.

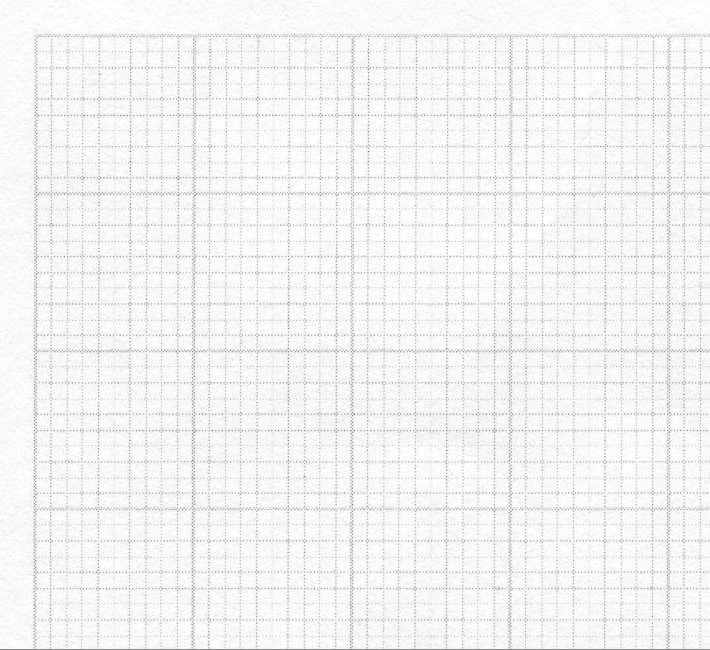

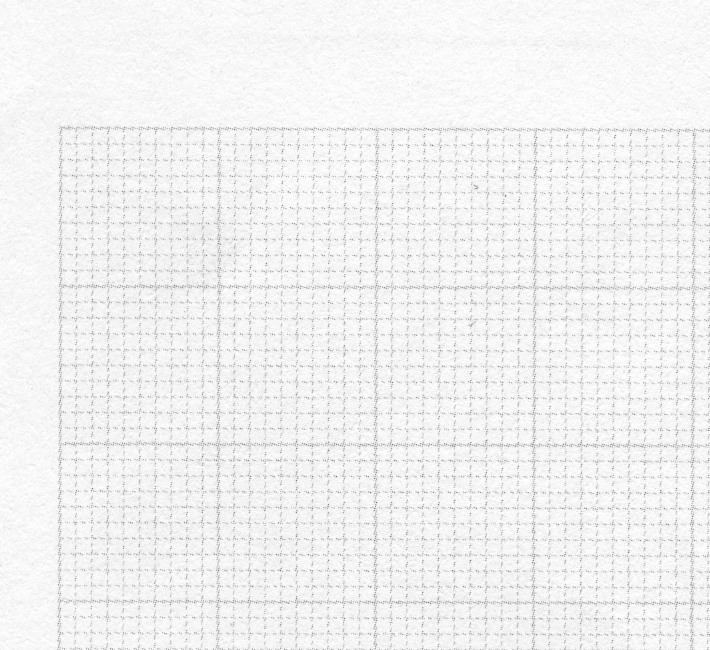

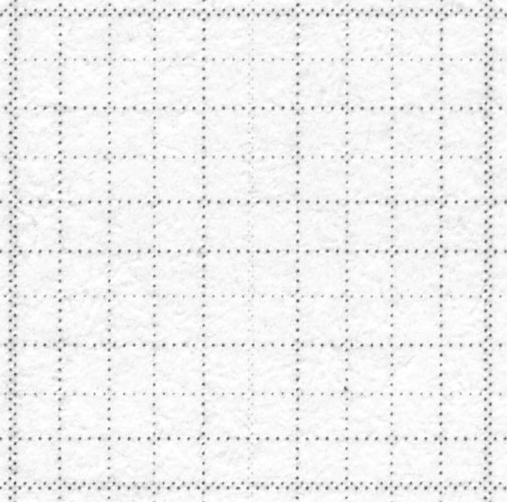

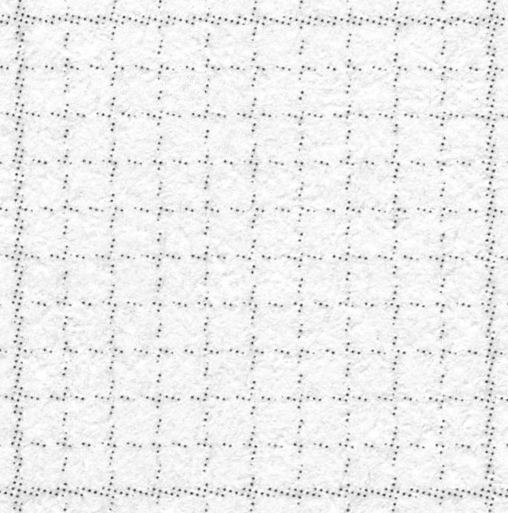

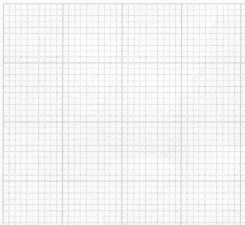

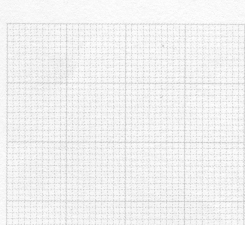

We recently had a very exciting example at hand. A notepad was printed with a millimetre grid in screened black. Picture 1 on the left shows the millimetre grid with a 45° screen angle in black and a 70 screen. Sometimes vertical lines are missing and at the bottom horizontal lines are completely missing due to the screen overlay. Figure 2 on the right shows the same millimetre grid with 15° grid angle in an 80 screen. The millimetre grid is reproduced evenly.

Both notepads were produced on the same day in the same printing company.

Interestingly, the repro company that produced the printing plates had manually changed the print screen from 15° to 45° for the first set of plates on the left because they thought it would give the best result. However, the unsatisfactory result was immediately apparent during the press proof. A notepad with missing lines will certainly not be accepted by the customer. After resetting to the original screen angle of 15° and increasing the screen from 70 to 80, a harmonious reproduction of the millimetre screen could be achieved without difficulty.

Below are the two excerpts in more detail: