Proof cheap is a typical search term that people use in search engines to find a cheap, colour and legally binding proof. But what makes a cheap proof?

A proof is one that is produced according to the specifications of the latest revision of the proofing standard ISO 12467-7 and is within the tolerances of this standard. The current revision is ISO 12647-7:2016, which has been tightened even further with this standard and has been supplemented by a certified edition of spot colours such as PANTONE and HKS.

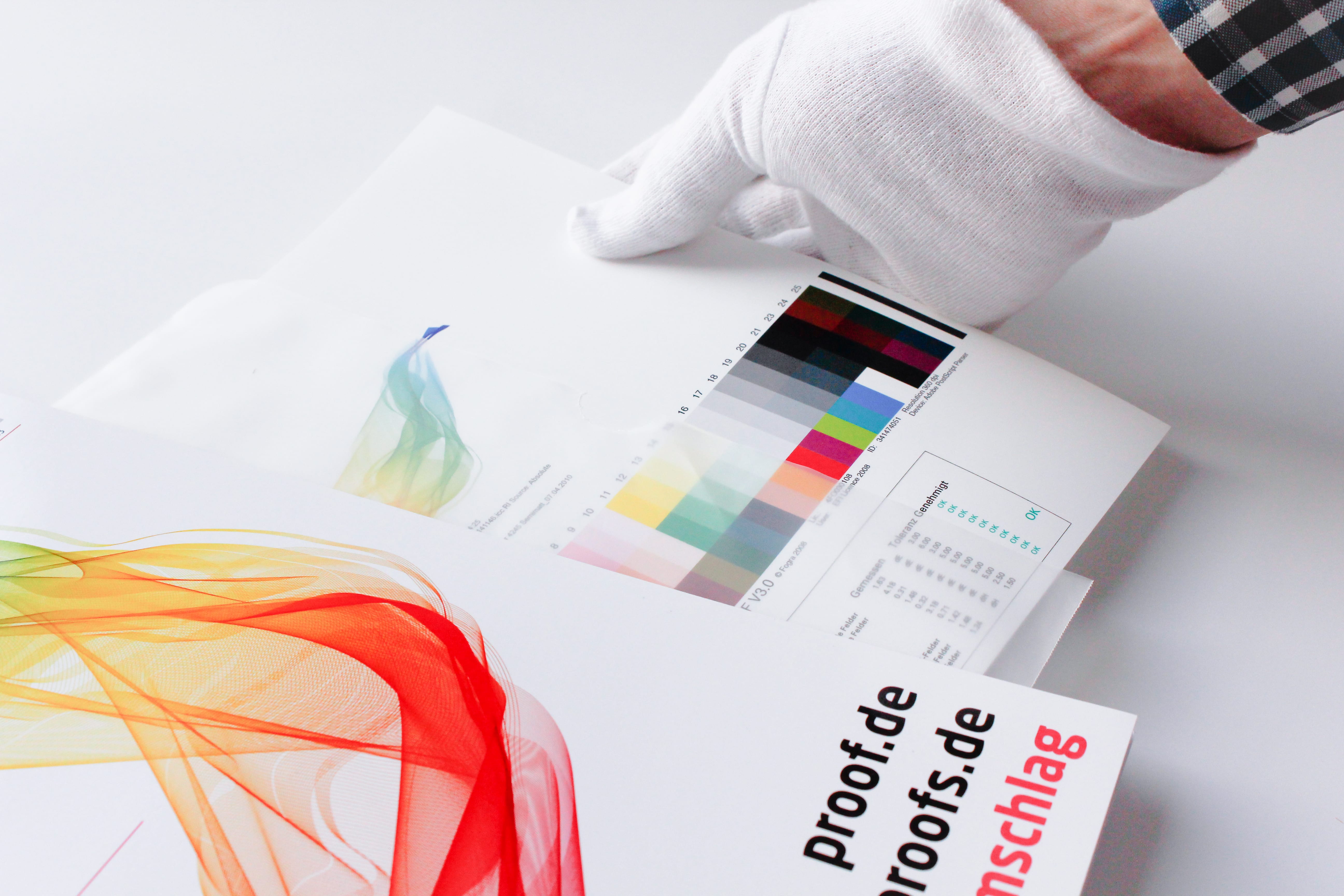

Such certified proofs can be ordered at shop.proof.de for all proof profiles.

But what makes the certified proof cheap? That’s the low price. Proofs are printed on certified proof papers on very high-quality pigment inkjet printers, usually using expensive proofing software, and measured with spectrophotometers. So how can production be done cheaply here?

1: Using cheap pigment ink?

One litre of ink for proofing devices is around 400 EUR, so it makes sense to use inexpensive alternative ink from China. The problem: there are no manufacturers – neither in China nor anywhere else – who produce inks that would actually produce similar inks in terms of pigment colour and spectral composition. I once called a manufacturer who advertises that his – already quite expensive – inks could also be used for proofing. When I asked him, he said: “No, no, that’s just for advertising, but of course I would never do that or recommend it, and I don’t know anybody who does that. As for the China inks, he said: “They start at 20 EUR per liter, but you get a different ink with every delivery, depending on where the wholesaler buys. Then they have to re-measure the proofer every time… forget it.” In addition, replacing a clogged print head costs around 2,500 EUR, so the risk is too high. A real proof therefore only works with original, very expensive ink.

2: Using cheap software?

GMG ColorProof, EFI Fiery XF and ORIS Color Tuner are just some of the most important proofing solutions on the market. What they all have in common is that proofing software is rather a niche software, so the programming effort is very high compared to the sales figures. Depending on the size of the output device and the range of functions in terms of verification, spot colour display or proofing on special materials such as transparent foils, etc., the software costs between 5,000 and 10,000 EUR, and in combination with other software products from GMG or Colorlogic it can quickly cost considerably more. Although there are a few low-cost solutions here too, these are usually irrelevant in professional proofing, as they are either not suitable for more than one workstation, or important functions such as spot colour libraries etc. are missing.

3: Using cheap proof papers?

There actually is a certain potential for savings in this area, really: the large manufacturers such as GMG and EFI naturally offer their own papers, which GMG, for example, has also implemented excellently in its software, as this naturally offers an opportunity to generate additional, permanent revenues through the sale of papers. But there are now numerous alternative suppliers who also offer Fogra-certified proof papers at prices that are sometimes over 30% lower. You can also save on the “quality” of the paper, e.g. on the grammage, by replacing a 245 g/m² paper with a 190 g/m² paper or by using a cheaper surface, but this is also noticeably cheaper in haptics and appearance at first glance.

4: Using cheaper proof printers and measurement technology?

There are really no ways to save money here. The two most important manufacturers EPSON and CANON don’t give each other much in terms of price, and with the cheaper printer models based on dye instead of pigments in the ink, it is not possible to produce satisfactory and durable proofs. On the one hand, the colourfulness of the pigment inks is not achieved, and on the other hand, the prints fade a lot faster and lose their original colourfulness sooner in the light.

Also concerning the measuring instruments there are not really any alternatives to the market leaders X-Rite and Konica-Minolta. Most of the times, the cheap colour measuring devices are only colourimeters and not spectrophotometers and have high tolerances between the single measurements and the measuring devices. Thus, also in this case, there is no real saving potential.

Conclusion: What makes the proof cheap

Within the four parameters ink, software, proof paper, printer and measurement technology, it is only possible to save on paper. But if we set the costs of the upper ranges as 25 percent each on the final product, then a saving of 30 percent on paper on the final product proof would only be 7.5 percent … and thus not very large. If, however, the surface and paper weight would have to be reduced and the final proof would look “cheaper”, then every saving would be a huge disservice. After all, the people who commission proofs – printers, agencies, designers and photographers – usually pass the proofs on to their customers, who use the proof to judge the quality of a retouch, a layout, a colour correction or a photo. In any case, a cheap or cheaper impression would be fatal for the client of the proofs.

A quality proof is a “manufactured product”

But a “really good” proof is not the sum of ink, paper, software and hardware. A good proof is always the result of expertise, care, meticulousness and a well-trained eye and ear.

When you speak about proofs, you must not forget the people who produce these proofs: Specialists, crude types, people with rough edges, but also passionate about what they produce with total commitment: proofs.

In our everyday life this starts with the ringing of the telephone: We have to be able to listen, understand problems, make suggestions, listen again, analyse procedures … in short: we have to be fit in the areas where the difficulties and problems of our proof customers arise.

We need to be able to design, layout, photograph and retouch so that we can talk to layouters, designers, photographers and retouchers and understand their software settings and parameters. We need to understand and have seen so much of printing that we can understand and reproduce typical printing difficulties of printers. We must also be able to understand problems and be able to give suggestions.

We need to know the differences between PDF/X-1a, PDF/X-3 and PDF/X-4, and be able to weigh up the pros and cons. We need to understand and be able to explain the problems of PANTONE and the resulting difficulties in representing PANTONE colours for printing and proofing spot colours.

We have to master our proofing software and be able to recognise potential problems if it does not want to measure again after an update, ignores jobs, outputs spot colours incorrectly or sometimes understands the same file and sometimes does not.

And last but not least we have to cut all pages by hand in the right place, pack them, stick the right label on the right carton, enclose the right invoice or send it to the right email address, have the right workarounds in mind so that the proofs can be sent neutrally with one or the other carrier, print delivery notes, and if time is tight, drive one proof to the UPS driver and the other to the DHL base.

Our proofs are a manufactured product. With hand, with passion, with brains. As rarely as possible with mistakes, though it happens sometimes. But always with great commitment. No wonder, therefore, that we did not want to accept any compromises with our proof papers either. We proof on what we consider to be the best papers. And not on the cheapest paper we could get. For you. For us. For our peace of mind :-). That’ s manufacturing.