It is actually quite simple to have proofs made. But experience shows that many customers often stumble over the same mistakes. We have put together the ten most important steps towards a successful proofing job:

- Proof as late as possible in the production process

- Select the right proof profile for your purposes

- Convert RGB or LAB images to CMYK

- Name Pantone and HKS colours correctly

- Proof your data in a 1:1 ratio and not scaled down

- Always proof with UGRA/Fogra Media Wedge 3.0

- Make sure that the job ticket is correct

- Make sure your service provider has the latest proof software and hardware

- Only accept authentic “contract proofs” according to ISO 12647-7

- Make sure that your proof provider has valid certifications

In the following we would like to present these individual points in more detail.

1. Proof as late as possible in the production process

The optimal solution is obvious: send the same data to the proof as you send to the print shop. This way you can make sure that the proof really matches the print. I remember a case where a complaint was made about an ad we proofed that contained a picture of a deserted corridor in a building: “The proof looks very different in colour from the print”. After a long search for errors in colour spaces and image formats, we noticed: The perspective of the proofed corridor was slightly different from the actually printed corridor. Why? At the last minute, the agency had swapped the original – and proofed – image for a slightly differently photographed image of the same aisle. It is immediately clear that the colour cannot be right here.

Therefore, if possible, proof the same data that you send to print or make sure that images and PDF export settings are identical for proof and print.

2. Select the right proof profile for your purposes

A proof is only colour-binding if it was created with the matching proof profile. If you want to proof a writing paper, you cannot proof according to ISOCoatedV2. ISOCoatedV2 is an image printing paper proof standard, whereas a letterhead is always printed on uncoated paper. Instead, you should select PSOUncoated as your proof standard. An ISOCoatedV2 proof will be much more colourful than could ever be printed on plain paper. And also for newspaper printing ISOCoatedV2 is not suitable, here you need an ISONewspaper 26v4 or similar.

An overview of all current proof profiles can be found here.

If the final print and therefore the proof profile is not yet fixed or no print profile is known (e.g. for roll-ups etc.) you can proof in ISOCoatedV2.

3. Convert RGB or LAB images to CMYK

The majority of all proofs are created from PDF files in X1-a or X3. Agencies and graphic designers either create their data in CMYK or convert colour spaces such as RGB or LAB to CMYK during PDF export. This has its justification:

Modern RIP software in printing companies or at the proofing provider can easily convert RGB or LAB colours into the CMYK proof colour space during proofing. However, it is possible that the printing company uses other RGB profiles (e.g. ECI-RGB instead of AdobeRGB 1998) or other rendering intents (e.g. “absolutely colorimetric” instead of “perceptive”) for the colour conversion from RGB/LAB to CMYK like the agency or proof manufacturer, which of course leads to a different colour result. You are therefore always on the safe side when you deliver all data in CMYK for proofing. Of course, spot colours are excluded from this, they should be created as additional colour separations.

4. Name Pantone and HKS colours correctly

For you, colour designations such as “the green from the last print job” or “customer red” may be unique colour designations. But the Proof-RIP cannot interpret such colour names correctly. You should therefore name colours explicitly in “HKS 41 K” and “PANTONE 217 C”. You can easily do this by selecting the colours in the Adobe programs from the provided Pantone and HKS libraries. Also important: For the printer an HKS 41 is an HKS 41, for the RIP an “HKS 41 K” is a completely different colour than an “HKS 41 N”, a “PANTONE 217 C” is a different colour than a “PANTONE 217 U”. So choose the right colour depending on the uncoated paper or picture print. A professional Proof RIP does not know a “HKS 41” or a “PANTONE 217”.

5. Proof your data in a 1:1 ratio and not scaled down

A proof is only meaningful if it is created in the same size as the subsequent print. Why? When data is calculated in detail, on the one hand details are swallowed and on the other hand parts of the image may be calculated differently. While a shirt with a checkered pattern of red and white in the DIN A3 original still offers some well distinguishable colours, its pedant scaled to DIN A6 might be only flat pink, as through the scaling, the check is converted to a surface. In this case, the proof is useless both for the evaluation in advance and for the printing. Therefore, it is better to proof a section 1:1 to the later final format than to break down the whole motif.

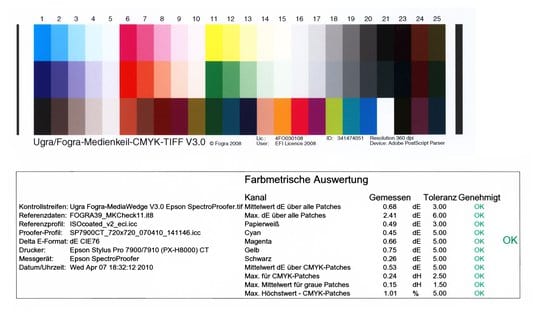

6. Always proof with UGRA/Fogra Media Wedge 3.0

A proof is only colour and legally binding if it contains a media wedge. Although the old media wedge in version 2.2 is still standard with some service providers, the media wedge has been published in version 3.0 for 8 years. So anyone who still proofs the 2 media wedge has probably not updated their proof software since 2008. Avoid these service providers. If you also have the media wedge provided with a test report, you and the printer can see at first glance that the proofed data is within the tolerances of the ISO standard.

Here is a current UGRA/Fogra Media Wedge CMYK V3.0 with test report:

7. Make sure that the job ticket is correct

According to ISO 12647-7, each proof must contain a job ticket with at least these requirements in a ” simple and understandable ” way:

- Name of the printing system (printer, software)

- Designation of the colourants (inks)

- Name of the substrate used

- Identification of the printing condition to be simulated

- Date and time of proof creation

- Date and time of the last calibration

- The used colour profiles, at least the used simulation profile and the rendering intent for the simulation

No less, but also not necessarily more must be printed on the proof.

8. Make sure your service provider has the latest proof software and hardware

Unfortunately we know service providers who have not calibrated their proof systems for more than 10 years. The proof software there is also still as of 2003, so it is obvious that proofs according to ISO 12647-7 can no longer be produced here. Although such companies sell proofs, they simply produce coloured paper. So make sure that your proof service provider uses the latest software and hardware. Especially when simulating HKS and Pantone colours, every new hardware and new software provides visible improvements. And even modern PDF formats like PDF X-4 cannot be processed correctly on old RIPs.

9. Only accept authentic “contract proofs” according to ISO 12647-7

The ISO standard is unmistakable:

ISO 12647-7 = “Contract Proof”

ISO 12648-8 = “Validation Print”

Nevertheless, the imagination of some service providers knows no bounds: ISO Raster Proofs, Swabian Proofs … they usually conceal a “Validation Print” according to ISO 12647-8, which at first sight only sounds like an eight instead of a seven behind ISO 12647, but: These so-called “Proofs” are actually only “Prints” and NOT colour- and legally binding, as higher tolerances apply for -8 than for -7! So before you order the very cheap ” wannabe proofs” of some service providers you should consider ordering a truly colour and legally binding “contract proof” according to ISO 12647-7 for a little more money. “Contract” stands for a contract between proof and printer. Fogra and ISO have done well to call only one product “proof” and the other just “print”. So please do not allow a “print” to be sold as a ” proof”. One is colour and legally binding, the other is not.

10. Make sure that your proof provider has valid certifications

Numerous proofing service providers advertise with Fogra logos on their websites. In fact, Fogra does certify proofing companies that have to undergo a detailed examination of their proofs. Fogra certifications go far beyond the mere testing of a media wedge and contain many other test criteria that must be fulfilled for certification. Fogra certifications expire after one year. The proof quality must then be reconfirmed by Fogra in the course of re-certification.

Many service providers shy away from having their quality checked again by Fogra, but still advertise years later with their certifications, some of which expired in 2008. You should only accept Fogra certificates that have been issued for “Contract Proof Creation” and bear a five-digit number. You can research this number at Fogra: https://fogra.org/en/certification/certified-persons-companies-and-products/contract-proof-creation-cpc

Once a result is output after entering the report number, the proof service provider has a currently valid certification that can be viewed. If no result is output, the service provider only advertises this, but does not have a valid Fogra certification. Unfortunately, this currently applies to numerous proof service providers, as Fogra does not check their certificates sufficiently.

Here you can see our valid Fogra certification for proof production according to Fogra 39 (2020)

You can see a valid Fogra certificate here (2013)

You can see a detailed Fogra test report on the certification here (2013)