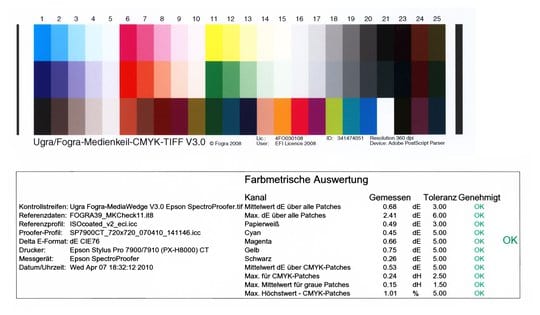

Fogra Fogra 51 and 52, optical brighteners and the new standards for offset printing and proofing are currently on everyone’s lips. In the proof area we still see only announcements and beta versions, but no real solutionsby now. In 2013 the reorganization of ISO 12647-2 was adopted for offset printing, but according to ECI the earliest “expected recommendation on the implementation of the new ISO 12647-2 as well as the provision of appropriate handouts and instruments’ will be in 2015. The current status of Fogra 51 and Fogra 52 from our perspective:

Color profiles:

- Fogra Fogra 51 and 52 have completed the beta phase at the Fogra in May 2014 and were forwarded to the ECI. The there in the project “fred15” compiled information and downloads are but from March, July to October 2014, but since then there has been no more news on the new standards. So there is currently no date for the release of the final profiles, handouts and tools foreseeable. Fogra, ECI, bvdm and UGRA continue to work together on the new standards.