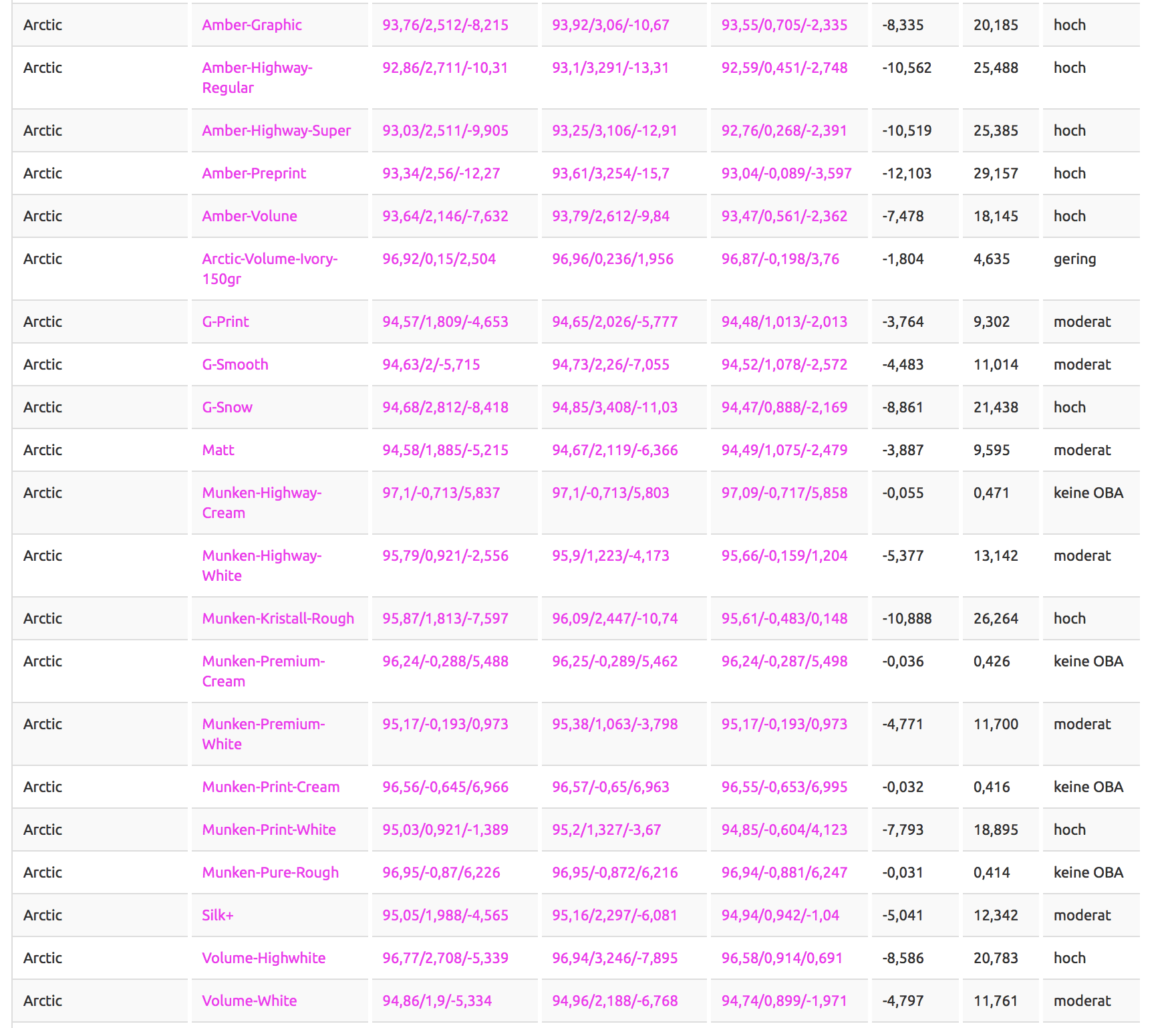

We have recently started offering DeviceLink colour conversions via DeviceLinks made by ColorLogic from numerous RGB and CMYK standards into other CMYK standards from offset and gravure printing.

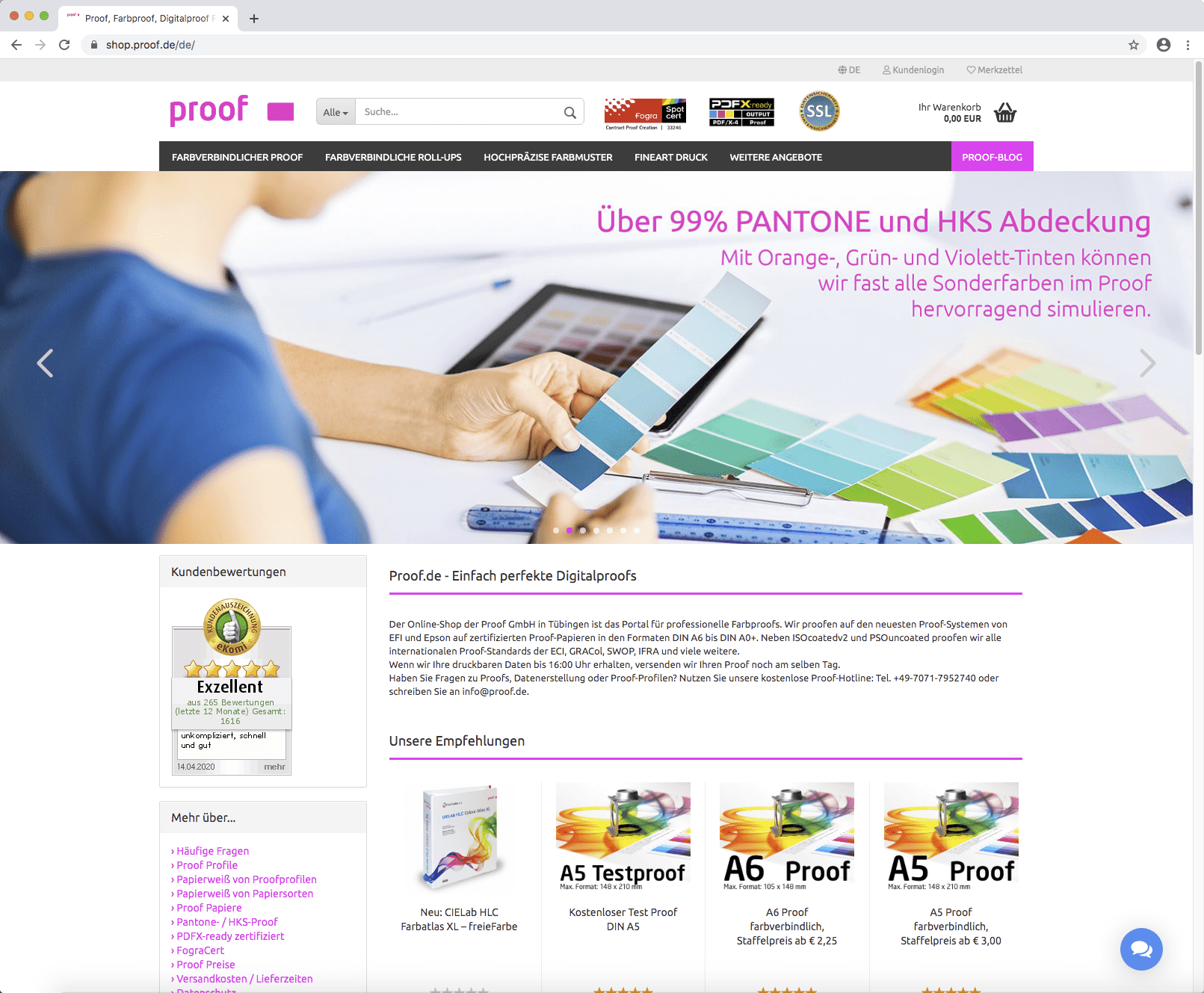

New at Proof.de: The EPSON SureColor SC-P9500 Spectro

Proof printer of the latest generation – now available at Proof.de: The new EPSON SureColor P9500 Spectroproofer. More speed for large proof jobs.