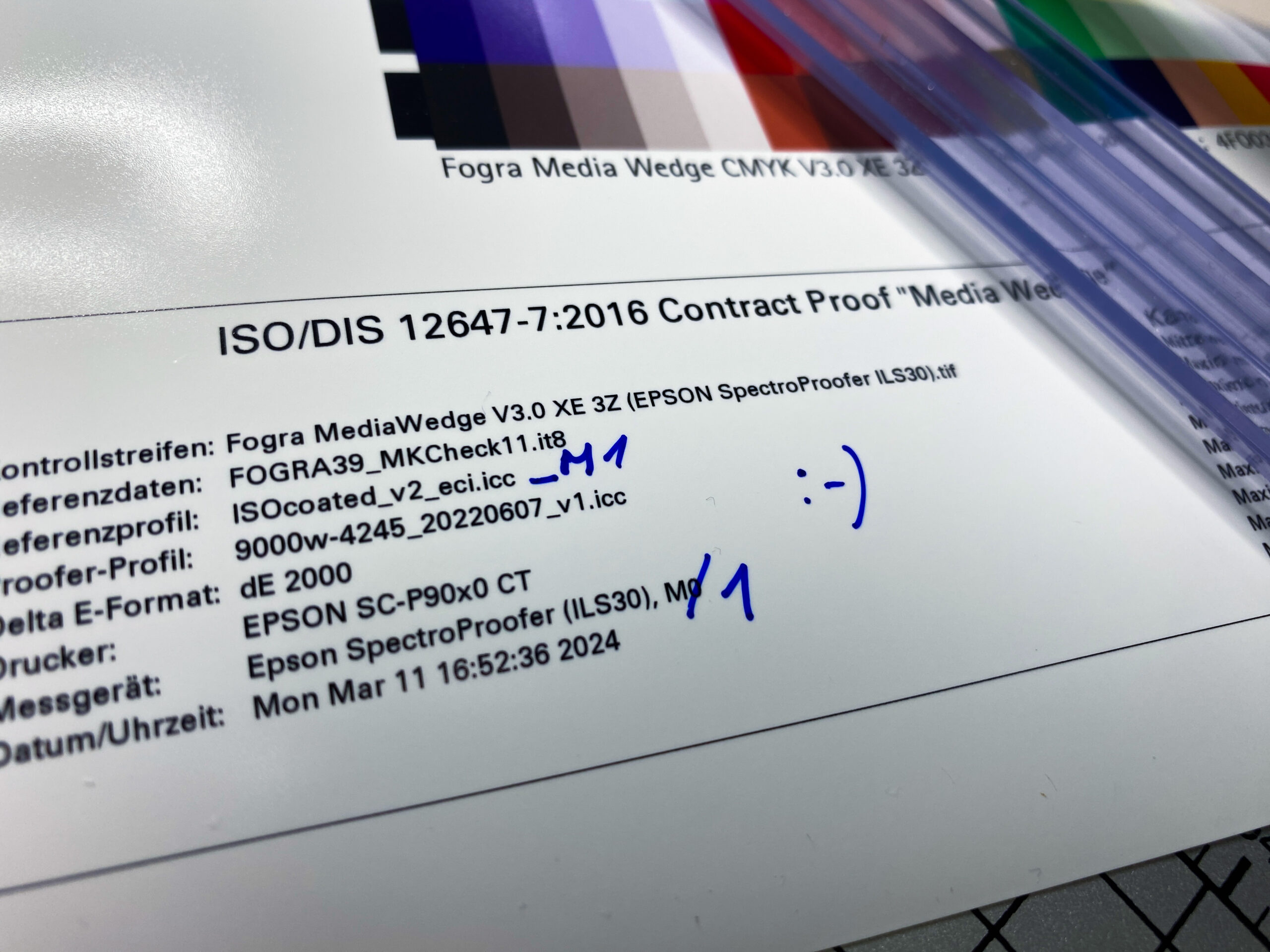

Shortly after ISO 12647-9:2021, part 9 of the printing standard for the metal decorating process with offset lithography, the characterisation data for Fogra60 and the matching ICC profile have now also been published by the ECI.

The colour profile is suitable for the production of CMYK offset prints on metallic substrates that have been printed with a white coating, i.e. flat printed metal sheets according to MC1 or Metal1. It doesn’t apply to formed or pre-formed metal, such as pre-formed cans.